Networking, Reliability, Performance, and Data Transparency in Automation

Future-proof your automation. SIMATIC components in protection class IP6x from Siemens

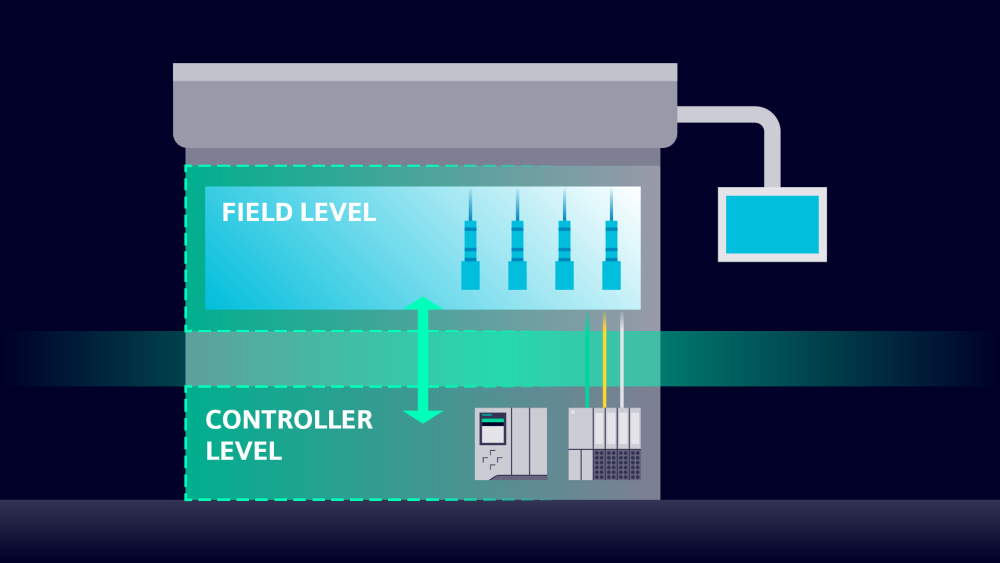

The requirement to increasingly shorten the lead time for the manufacture of new machines and at the same time to manufacture them as flexibly as possible to be able to quickly implement expansions or specifications is becoming more and more relevant. Placing I/O systems outside the cabinet lead to shorter cable lengths and therefore requires less wiring effort. This not only demands a decentralized structure of automation, but also an installation near the process where a high protection class in IP6x is mandatory.

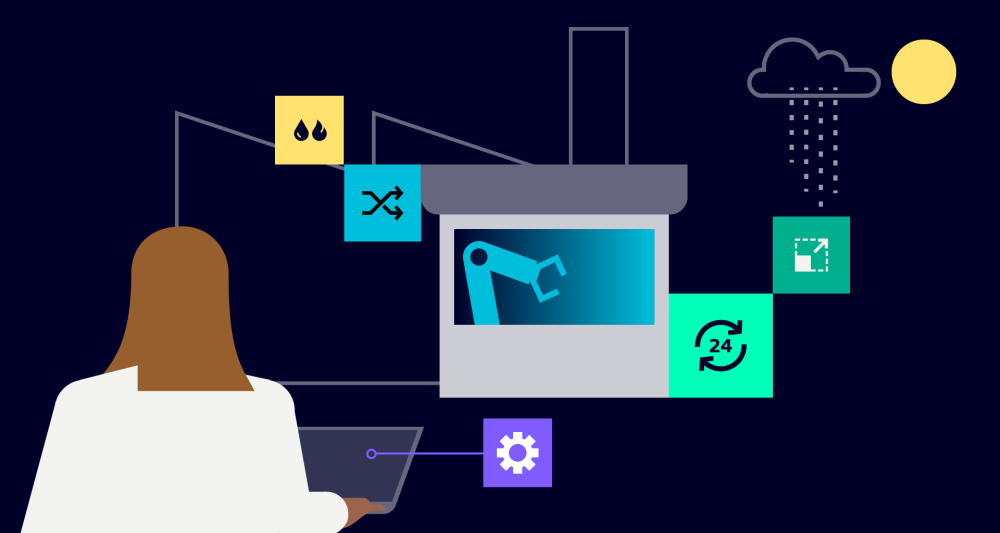

The advancing digitalization in industry demands a significantly higher data throughput of the machines, not only in the production process directly, but also in the exchange with the IT level. At the same time, plant operators are striving for an ever-higher degree of automation of their operational processes to increase productivity. This requires that machines can be easily integrated into the production environments of plant operators and that standardized interfaces are available for data exchange. A decentralized, machine-oriented concept is the right way to go here.

If an industrial customer is globally active, the machine manufacturer also has to take different local conditions into account in the machine concept. A decentralized structure with a high degree of protection can be an option.

Accelerating Market Solutions with Decentralized Automation and High-Protection Modules

Last but not least, new solutions must be brought to market faster than before, while still remaining flexible enough to accommodate changing or new customer requirements. At the same time, efficiency in planning and engineering must be improved to be able to offer cost-effective production solutions. Simply leaving space in an existing control cabinet for future HW components is therefore only the second choice today. Rather, one should think in the direction of decentralized construction, where extensions are connected with decentralized automation, which are mounted directly on the new system components and are designed with a high degree of protection such as an IP6x rating.

The comprehensive product range from the Siemens modular automation system can help in many cases. In particular, the components of the SIMATIC ET 200 peripheral system offer a wide range of possibilities when high degrees of protection are required. There is a choice of modules from the product families of SIMATIC ET 200AL and and ET 200pro with IP65/67 rating, ET 200eco PN with IP69K rating as well as the SIMATIC ET 200clean (releasing in 2025) for specific product sectors with highest hygienic demands, all designed for different robustness requirements.

Scalable, Flexible Automation with Multi-Protocol and IO-Link Integration

If a machine reaches the limits of its communication capabilities due to additional tasks, it is possible to switch to a more powerful controller, because SIMATIC ET 200 modules with IP6x rating is scalable and modular too. If different communication standards are required, the MultiFieldbus interface module is recommended, which is also available in various IP6x ratings. In addition to PROFINET, ET 200 stations can also be connected to controllers that communicate via Modbus TCP or EtherNet/IP. This gives freedom and helps to open up new markets that rely on other standards.

And anyone who has installed intelligent IO-Link-capable sensors in their plant can easily integrate their data into their automation system via IO-Link modules from the ET 200 series. Regardless of whether binary or analog, the wiring remains the same, and in addition more information, e.g. diagnostics data, can be read from the sensor. This increases plant availability and helps with diagnostics and maintenance.

Streamlined Control with Decentralized ET 200 Modules and Scalable HMI Solutions

The decentralized design of control and communication with ET 200 components simplifies cabling, the structure can be easily expanded, and space in the control cabinet can be saved because ET 200 modules with the IP6x rating can be mounted directly on the machine.

As for the operators who visualize and operate the machines with special protection requirements, whether the devices need to be protected against dust, humidity or dirt, the broad SIMATIC HMI PRO system portfolio provides scalable, configurable solutions in protection class IP65. A wide range of extensions mean the panels and industrial PCs can be adapted to suit the requirements.

Ideal for every task, these devices contain everything from visualization to PC-based control tasks and decentralized HMI solutions with a client-server architecture. Available in sizes from 12 to 24 inches, the PRO devices in the HMI Comfort Panel / Unified Comport Panel, Industrial Flat Panel, Industrial Panel PC, and Industrial Thin Client series offer the perfect solution for your protection needs.